| Hobart

Conveyor Type Dishwasher |

|

|

Model:

CL44E |

| Our

Price:

Click "Order"

to see price

|

¡¡ |

| Availability:

In Stock |

| Manufacturer:

Hobart |

| |

| - |

|

|

|

| Hobart®

Dishwasher |

Hobart¡¯s

CLe and C-Line models are all ENERGY STAR® rated, saving you

energy and water on every cycle.

With their Hobart-exclusive Opti-Rinse™ technology using

less than half the rinse water and half the energy compared

to models without it, the CLe and C-Line warewashers can

save you more than $9,000 and $6,000 a year, respectively.

ENERGY STAR rated, they are essential components of any

sustainable foodservice operation.

In medium- and

high-volume operations where the dishes keep on coming, the

racks have to keep on rolling. Hobart reliability and

dependability are legendary. In fact, Hobart warewashers

have the highest documented uptime in the industry.

Constructed of stainless steel, both the CLe and the C-Line

are built to last for years, saving you energy, water and

money for years. |

|

|

| Features: |

When it comes to saving, Hobart CLe

Warewashers let you really clean up.

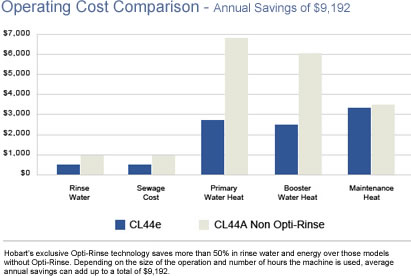

Start by saving up to $9,192 a year. That¡¯s how much

you could save with Hobart¡¯s exclusive Opti-Rinse™

technology. Opti-Rinse technology reduces water

consumption so dramatically, the final rinse water

required could be as low as .39 gallons per rack.

A small boost for big savings. The CLe is so

efficient, the specifications for a booster heater

continue to be reduced. Small in size, it costs less and

requires less energy.

|

|

|

Putting

saving on automatic. To preserve energy, the CLe

has an Auto-timer that automatically shuts off the

pumps and conveyor after a preset time, once the

rack exits the machine. It restarts the warewasher

when a rack re-enters. And every CLe

Warewasher has an exclusive Energy Saver mode that

can be set by the customer to automatically shut off

the entire dish machine, except for the controls,

after one to six hours of inactivity, for even more

saving. Even

Hobart¡¯s tanks are designed to save you money.

They¡¯re deeper, creating a smaller surface area,

which helps maintain water temperature and reduces

energy. The deep tank design also requires fewer

refills, saving water and detergent, too.

¡¡ |

|

|

The cascading water system on

the multi-tank models replenishes each tank with the heated

water from the prior tank as it goes from the final rinse to

prewash zone, saving energy and water. Hobart¡¯s

patent-pending thermal layered curtains reduce heat loss at

both the load and unload ends on an average of 2ºF to 3ºF.

And the door-actuated drain closures ensure that the drains

are closed¡ªsaving water, energy and detergent.

There¡¯s even a highly effective

Power Scrapper prewash specifically designed for heavier

food-soil removal. It uses the heated, detergent-filled

water from the wash tank, saving not only water and energy,

but labor and detergent, too. The wash water also stays

cleaner longer, reducing the need for refills.

Hobart CLe

Warewashers offer unrivaled reliability and durability for

lower cost of ownership. A machine doesn¡¯t become

the most popular conveyor warewasher in the industry unless

it delivers day in and day out. Over the decades, you¡¯ve

come to rely on our durability and performance. Your trust

is well founded. Hobart Warewashers have the highest

documented uptime in the industry. Hobart, CLe and

reliability are one and the same.

Painstaking attention to all

the details. Its durability and long life start with a

heavy-gauge, stainless steel frame, legs and tanks, which

together add greater strength and structural integrity to

the entire unit. The dual-point drive reduces stress on the

conveyor drive for increased reliability. The double-walled,

insulated stainless steel doors and heavy-duty stainless

steel brackets stand up to the toughest possible use.

Features that add peace of

mind and protection. A variety of features helps ensure that

the CLe is reliable and hard-working. The

self-draining stainless steel pump and impeller provide

trouble-free longer life and no bacteria-laden water in the

pump. And an integrated pump intake screen keeps debris out

of the pump, reducing downtime. The screen is removable for

easy cleaning. |

|

Never has so much productivity been so easy to use. |

|

| To tell

how well the CLe Warewasher is performing,

all the operator has to do is glance at the digital

display to verify the machine status and

temperatures. The CLe¡¯s conveniently located,

top-mounted, NAFEM Data Protocol compliant controls

can be programmed to notify the operator when it is

time to delime the machine or to take necessary

action if low temperatures or dirty tank water is

detected. And the auto-fill feature simplifies

operation while ensuring optimum tank water levels. |

|

|

The CLe

Warewasher is very considerate of your staff¡¯s

comfort, too. The insulated front of the CLe

model not only helps keep the heat¡ªand noise¡ªinside,

but also makes the outside cooler to the touch by

33%. |

|

|

Up to 8,550 dishes an

hour. There¡¯s a size and model of CLe

Warewasher to match your operation¡¯s volume and specific

dish-soil-removal needs that will keep your staff productive

and your dishroom running smoothly. Choose the model that¡¯s

right for you¡ªfrom 202 to 342 racks per hour. That

translates into 5,050 to 8,550 dishes.

Built into every CLe

Warewasher is the exclusive, patent-pending Rapid Return™

drive system that delivers a more consistent and even motion

of the racks through the warewasher, improving the wash and

rinse results. Further ensuring a smooth operation is

Hobart¡¯s dual-pawl drive mechanism, which reduces jams by

simultaneously pushing the racks from each side, allowing

for a full wash and rinse spray pattern across the ware. |

|

Hobart¡¯s Computational Fluid Dynamics (CFD) wash

manifold design increases wash performance by up to

5% over conventional models. This exclusive feature

creates a more balanced wash pattern that allows for

a larger separation between the wash and rinse

zones, and also minimizes the carryover of food soil

and cooler water into adjacent tanks.

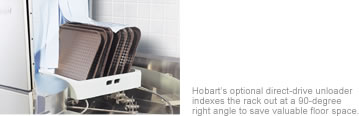

Hobart¡¯s optional DDU38

direct-drive unloader indexes the rack out at a

90-degree right angle to save valuable floor space. |

|

|

|

Easy to install and, if

necessary, simple to service. With single-point

drain, water and electrical connections, installation is

simplified. The CLe can also be converted to low-

or high-temperature sanitation in the field.

Diagnostics built into the

warewasher¡¯s software makes service more efficient. Which

means you can be up and running faster, with less downtime

and at a higher level of efficiency than ever.

Inch for inch, the

most productive and accommodating conveyor warewashers in

the industry. The Hobart CLe packs more

productivity into every square inch than ever before. That¡¯s

what let us reduce not only the number of models but also

the whole line to a very accommodating length¡ªfrom 44" to a

maximum of 86". Our longest model is now a full 38" shorter.

That means you can pack more productivity into even smaller

dishrooms. To assist you in specifying your next CLe

Warewasher, contact your local Hobart sales representative

for a no-obligation site survey to analyze your needs and

provide an efficient dishroom analysis, highlighting areas

that will reduce operational costs and improve productivity. |

|

The

doors on the CLe open a new era of easy access and

cleaning in conveyor-type warewashers.

The CLe Warewasher¡¯s

large, hinged doors open wide for easy access to the

machine¡¯s interior. Inside you¡¯ll find that the stainless

steel Computational Fluid Dynamics designed wash arm

manifolds are not only easy to take off and clean, but

they¡¯re also self-aligning, ensuring proper positioning and

a uniform spray pattern. And the Auto-Position™

rinse arms are designed to ensure that the rinse arms and

nozzles are properly positioned for a consistent, sanitizing

rinse pattern. |

|

Easy to

access and simple to clean. The easy-access

drain lever is located outside the water zone for

operator convenience. And a single strainer pan and

basket mean fewer things to remove for breakdown and

cleaning. The wash pipe is also mounted on the

exterior of the machine, providing a clutter-free

interior, further simplifying wipe-down. |

|

Standard Features:

¡ö 202 racks per hour

¡ö Opti-RinSe™ system

¡ö Patent Pending Rapid Return Conveyor Drive Mechanism

¡ö Insulated hinged double doors with door interlock switches

¡ö Patent Pending Door Seal System

¡ö 19.5 inch chamber height opening

¡ö Top mounted micro-processer control module

¡ö Energy saver mode

¡ö Dirty water indicator

¡ö Low temperature alert

¡ö Conveyor dwell

¡ö Delime notification

¡ö Service diagnostics

¡ö NAFEM Data Protocol compliant

¡ö Patent Pending Computational Fluid Dynamic Designed Self-Aligning Wash Manifolds

¡ö Stainless steel debossed anti-clogging wash arms

¡ö Patent Pending Removable Integrated Pump Intake Screen

¡ö Stainless steel self-draining pump and impeller

¡ö Single, sloping scrap screen and deep basket

¡ö Stainless panels enclose perimeter and bottom

¡ö Door actuated drain closure

¡ö Single point electrical connection

¡ö Convertible hot water or low temp final rinse

¡ö Vent fan and booster heater control

|

|

|

|